Integrating ACT and PDCA: A Continuous Improvement Case Study at Regen Allograft

In today’s dynamic business landscape, project management approaches that adapt traditional frameworks to real-world needs can drive exceptional improvements. When managing improvement projects, structured frameworks like PDCA (Plan-Do-Check-Act) offer a continuous cycle for systematic change. However, PDCA’s assumption of continuity leaves out the initiation and closing phases of the project life cycle, as defined by PMBOK (Project Management Body of Knowledge). To address this, the ACT (Analyze, Coach, Transform) framework offers a holistic approach, especially beneficial for consultants managing continuous improvement projects. In a recent project at Regen Allograft, we implemented both ACT and PDCA to resolve friction between sales and warehouse teams, ultimately removing operational bottlenecks and aligning goals for lasting improvement.

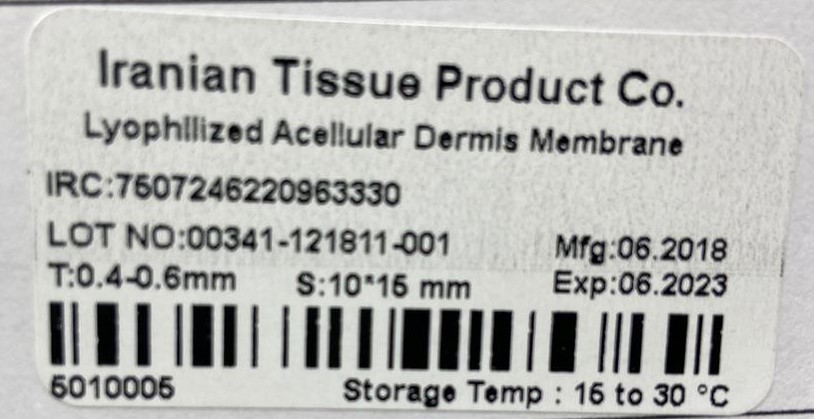

Old Labels

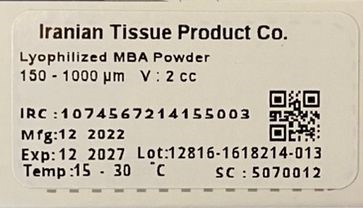

New Labels

Initiation and Analysis: Setting the Stage with ACT’s Analyze Phase

As with any improvement project, a solid understanding of the current state and goals was essential. Using the Analyze phase of the ACT framework, we started by identifying key issues in warehouse operations and interdepartmental pain points.

A GEMBA walk revealed that while barcodes were present on all labels, warehouse staff weren’t using barcode scanners due to system limitations. The ERP system could only interpret SKU codes, not the unique lot numbers essential for tracking medical products. Additionally, local software used in the packaging department generated these labels, but it wasn’t compatible with the ERP, complicating label customization and regulatory compliance.

The ACT Analyze phase provided clarity on operational inefficiencies, allowing us to pinpoint bottlenecks and understand interdependencies, which laid a crucial foundation for the next stages.

Coaching: Building Cross-Departmental Understanding and Alignment

With our analysis complete, we moved into the Coach phase of ACT, where interdepartmental collaboration became essential. The Quality Assurance (QA) and Systems teams were initially resistant to changing labeling practices, given that they had previously approved the setup.

Coaching sessions provided an opportunity to educate these departments on the downstream impacts of their processes on warehouse operations, highlighting how the lack of detailed labels burdened both warehouse and sales teams. Through this awareness-building phase, we cultivated a collaborative mindset that prepared each team to contribute actively to problem-solving, a necessary cultural shift that required more than just technical solutions.

Transforming Operations and Leveraging PDCA for Sustainable Change

In the Transform phase, we began implementing changes, with PDCA guiding the continuous improvement process. Here’s how ACT and PDCA worked together:

Plan: We started by addressing the label format, working with the ERP provider to update the system so barcode readers could scan newly formatted labels. A pilot program was developed using Excel and VBA, producing labels with a new QR code format, which enhanced flexibility and encoded both SKU and lot numbers for accurate tracking. To streamline label production, we also connected this program to Bartender software, a flexible, industry-standard tool for barcode and QR code generation.

Do: Implementation involved adding barcode readers, computers, and expanding workspaces. In the packaging department, where the label production process had previously limited throughput, switching from barcodes to QR codes simplified workflows significantly. This transformation quadrupled the department’s capacity with only a doubling of staff, freeing it from its role as the bottleneck in the production chain.

Check: With the new processes in place, we regularly monitored outcomes. Were deliveries now on time? Was the warehouse better equipped to handle product movements? The feedback loop we created allowed us to make real-time adjustments as needed, ensuring every aspect of the changes was effectively contributing to smoother operations.

Act: Based on insights from monitoring, we fine-tuned workflows, ensuring optimal performance across departments. In the warehouse, using the Excel and VBA pilot program allowed bulk data uploads to the ERP system, eliminating manual data entry errors and significantly reducing workload.

Project Closure and Delivering Lasting Impact

Closing the project was straightforward, thanks to the ACT framework’s structured phases, which built alignment and simplified transitions. With all changes well-documented and teams fully trained, we were able to hand over a system that empowered sales, warehouse, and packaging departments to work efficiently and cohesively.

This project serves as a strong example of how the ACT framework complements PDCA, bridging gaps to address real-world project needs. While PDCA supports continuous refinement, ACT enables structured initiation, analysis, and transformation, ultimately closing the loop for long-term success.

By combining ACT and PDCA, we not only increased operational efficiency but also fostered a culture of collaboration and continuous improvement at Regen Allograft. This integrated approach not only removed bottlenecks but created lasting organizational value and a solid foundation for future growth.